Case Study

Scope of Service

We inspect materials, components, and complex installations of all stages of the products lifecycle. BIE have inspectors based near all key manufacturing locations who are backed by a network of global coordination offices. Whether it be a one-day visit or a long-term residency, BIE can quickly dispatch qualified and trained technical specialists to supplier facilities to oversee inspections and tests, review and witness special processes, verify measurements and testing results, assess workmanship, and report supplier progress.

The scope of the inspection is determined by the Client and can range from a single final inspection to a full program starting with a pre manufacturing meeting through all stages of the equipment’s manufacturing life cycle to a final pre shipment inspection and release.

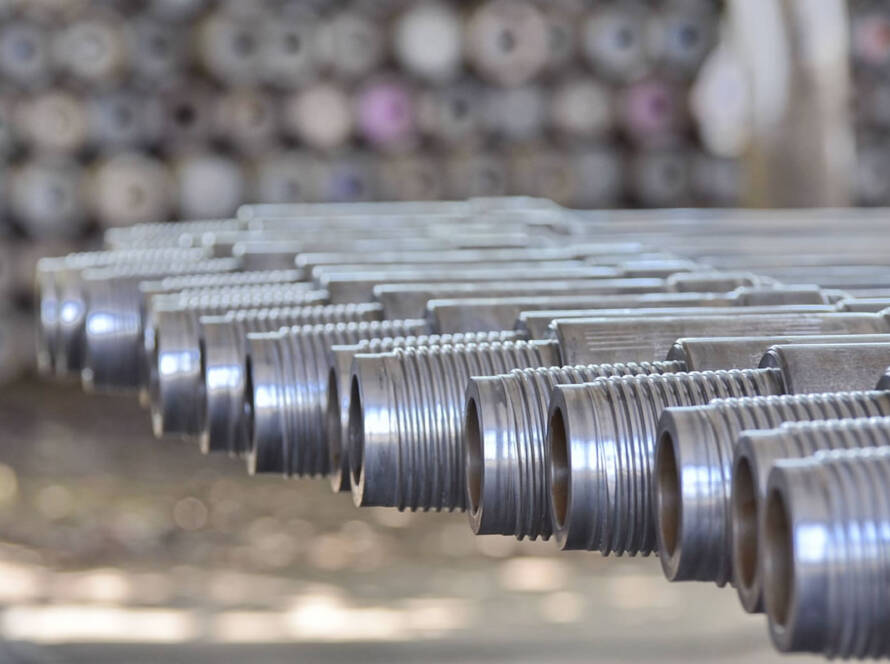

Our expertise includes the inspection of material, machinery, and manufactured items, such as valves, fittings, piping and fabrications supported by an in-depth knowledge of manufacturing, welding and fabrication, instrumentation and control systems, coatings and non-destructive testing.

Rapid Response – BIE provide a rapid response to Client’s requirements as we understand that time and project over run is costly.

Tailored Service – Each Client has different requirements so BIE tailors its processes to meet a client’s individual needs and budget.

Global Reach – BIE has field personnel located near most major key manufacturing centres throughout the world who are supported by a network of global coordination offices.

“Report Turnaround Time and Report Accuracy are key business KPI’s and are continually monitored”

Equipment

| Project | Equipment | Vendor Location |

|---|---|---|

| Project | Equipment | Vendor Base |

| Project A | Printed Circuit Heat Exchangers | United Kingdom |

| Project B | CS & Ti Shell & Tube Heat Exchangers | Sinapore |

| Project C | Structural Steelwork | China |

| Project D | Pig Launchers/Receivers | Italy |

| Project E | Heat Exchanger | Italy |